| The Following is a chart showing foot dimensions and their relative boot sizes. | ||||||

| Foot Length | Boot Size | |||||

|---|---|---|---|---|---|---|

| US | AUS | AUS | Mondo | |||

| Inch | Cm | Men | Women | UK | Europe | Point |

| 8 | 20.3 | 2 | 3 | 1 | 33.0 | 21.3 |

| 8 1/6 | 20.7 | 2½ | 3½ | 1½ | 33.6 | 21.7 |

| 8 1/3 | 21.2 | 3 | 4 | 2 | 34.3 | 22.2 |

| 8½ | 21.6 | 3½ | 4½ | 2½ | 34.9 | 22.6 |

| 8 2/3 | 22.0 | 4 | 5 | 3 | 35.5 | 23.0 |

| 8 5/6 | 22.4 | 4½ | 5½ | 3½ | 36.2 | 23.4 |

| 9 | 22.9 | 5 | 6 | 4 | 36.8 | 23.9 |

| 9 1/6 | 23.3 | 5½ | 6½ | 4½ | 37.5 | 24.3 |

| 9 1/3 | 23.7 | 6 | 7 | 5 | 38.1 | 24.7 |

| 9½ | 24.1 | 6½ | 7½ | 5½ | 38.7 | 25.1 |

| 9 2/3 | 24.6 | 7 | 8 | 6 | 39.4 | 25.6 |

| 9 5/6 | 25.0 | 7½ | 8½ | 6½ | 40.0 | 26.0 |

| 10 | 25.4 | 8 | 9 | 7 | 40.6 | 26.4 |

| 10 1/6 | 25.8 | 8½ | 9½ | 7½ | 41.3 | 26.8 |

| 10 1/3 | 26.2 | 9 | 10 | 8 | 41.9 | 27.2 |

| 10½ | 26.7 | 9½ | 10½ | 8½ | 42.5 | 27.7 |

| 10 2/3 | 27.1 | 10 | 11 | 9 | 43.2 | 28.1 |

| 10 5/6 | 27.5 | 10½ | 11½ | 9½ | 43.8 | 28.5 |

| 11 | 27.9 | 11 | 12 | 10 | 44.5 | 28.9 |

| 11 1/6 | 28.4 | 11½ | 12½ | 10½ | 45.1 | 29.4 |

| 11 1/3 | 28.8 | 12 | 13 | 11 | 45.7 | 29.8 |

| 11½ | 29.2 | 12½ | 13½ | 11½ | 46.4 | 30.2 |

| 11 2/3 | 29.6 | 13 | 14 | 12 | 47.0 | 30.6 |

| 11 5/6 | 30.1 | 13½ | 14½ | 12½ | 47.6 | 31.1 |

| 12 | 30.5 | 14 | 15 | 13 | 48.3 | 31.5 |

| 12 1/6 | 30.9 | 14½ | 15½ | 13½ | 48.9 | 31.9 |

| 12 1/3 | 31.3 | 15 | 16 | 14 | 49.5 | 32.3 |

| 12½ | 31.7 | 15½ | 16½ | 14½ | 50.2 | 32.7 |

| 12 2/3 | 32.2 | 16 | 17 | 15 | 50.8 | 33.2 |

| 12 5/6 | 32.6 | 16½ | 17½ | 15½ | 51.5 | 33.6 |

| 13 | 33.0 | 17 | 18 | 16 | 52.1 | 34.0 |

| 13 1/6 | 33.4 | 17½ | 18½ | 16½ | 52.7 | 34.4 |

| 13 1/3 | 33.9 | 18 | 19 | 17 | 53.4 | 34.9 |

| Inch | Cm | US | US | UK | Europe | Mondo |

| Men | Women | Point | ||||

| Inter size gap | 1/3" | 1/3" | 1/3" | 2/3 Cm | 1 Cm | |

| Inter size gap " | 1/3" | 1/3" | 1/3" | 0.26" | 0.39" | |

| Inter size gap mm | 8.5 mm | 8.5 mm | 8.5 mm | 6.7 mm | 10 mm | |

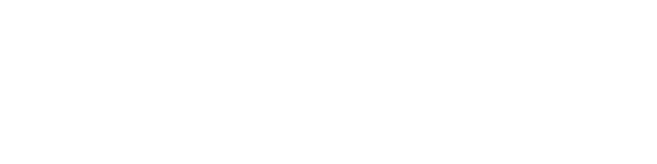

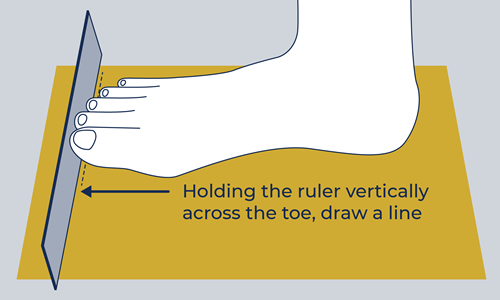

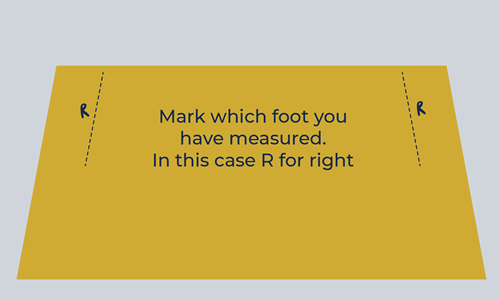

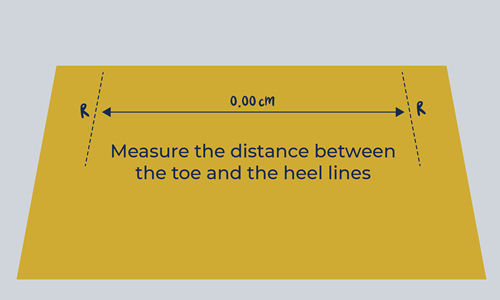

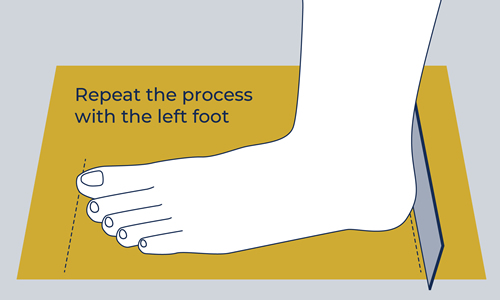

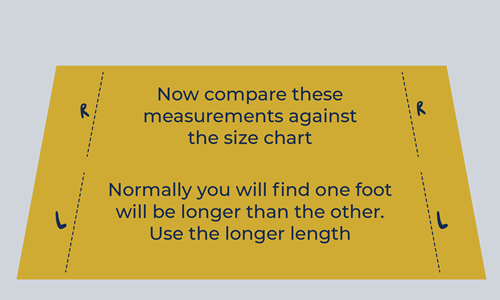

Guide to Measuring Your Correct SizePlease follow this guide in order to measure your feet accurately. You will need to have someone else actually take the measurements as you need to be looking up, not down, whilst the measurements are being taken to keep even pressure on the foot to avoid distortion. |

|

|

|

|

|

|

×

SIGN UP FOR NEWS, OFFERS AND EXCLUSIVE DISCOUNTS

Join our community and be the first to know about exclusive offers, new product launches and insider news, delivered straight to your inbox.

Simply enter your name and email address to subscribe, and never miss out on the latest from Harold Boots.

Simply enter your name and email address to subscribe, and never miss out on the latest from Harold Boots.